Modular & Multi-Span Ironwork Solutions

Designed for complex chamber layouts, linked covers, and

multi-unit installations—delivered with precision and durability.

The Ironmaster™ system from Rhino provides a robust engineering solution for the replacement, re-bedding, and reconstruction of multi-span access covers and frames—including modular, linked, or oversized chamber installations.

Why Multi-Span Ironwork Fails

Common causes of failure include:

✅ Breakdown of the supporting structure

✅ Cracked or degraded mortars

✅ Frame movement or deformation

✅ Surround settlement or surface wear

✅ Fatigue or damage to the lids

In reality, once failure occurs, the exact root cause is often unclear—especially on busy networks. That’s why our approach is comprehensive.

Built to Tackle Every Weak Point

Rather than treating the symptoms, we address all potential failure mechanisms. Our teams ensure every element is properly:

- Rebuilt

- Reinstated

- Re-bedded

- Up to standard

With Ironmaster, you get a durable, compliant, and future-proof solution—engineered for long-term performance, even in the most demanding locations.

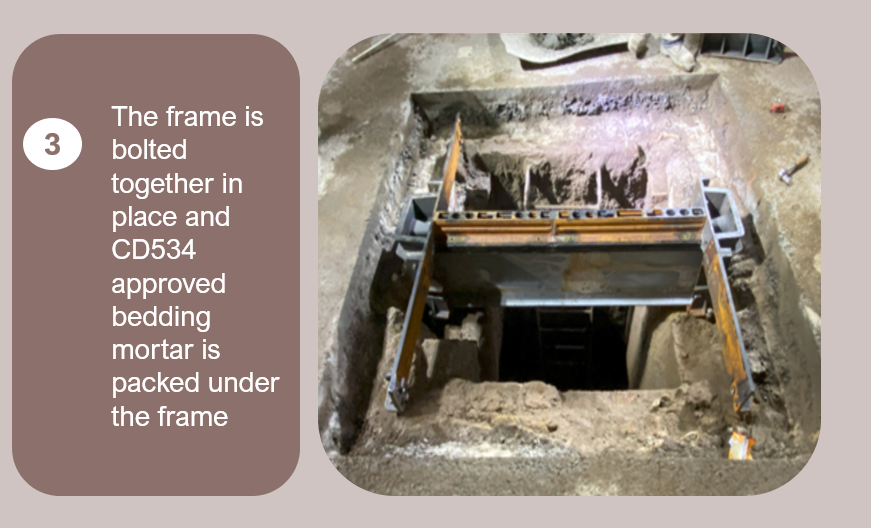

Fleet Street, London

Images show Fleet Street in construction. These do not portray the final look of the Modular Large Access Cover.

Permanent Solutions for Collapsed Multi-Span Covers

When large modular or multi-span access covers begin to fail, a temporary asphalt patch may offer short-term relief—but continued stress on the frame will eventually lead to full collapse. That’s where Rhino Asphalt Solutions comes in.

We’ve developed a dedicated specialist team to replace and reinstate collapsed or deteriorating multi-span ironwork using our BBA HAPAS-approved Ironmaster™ system.

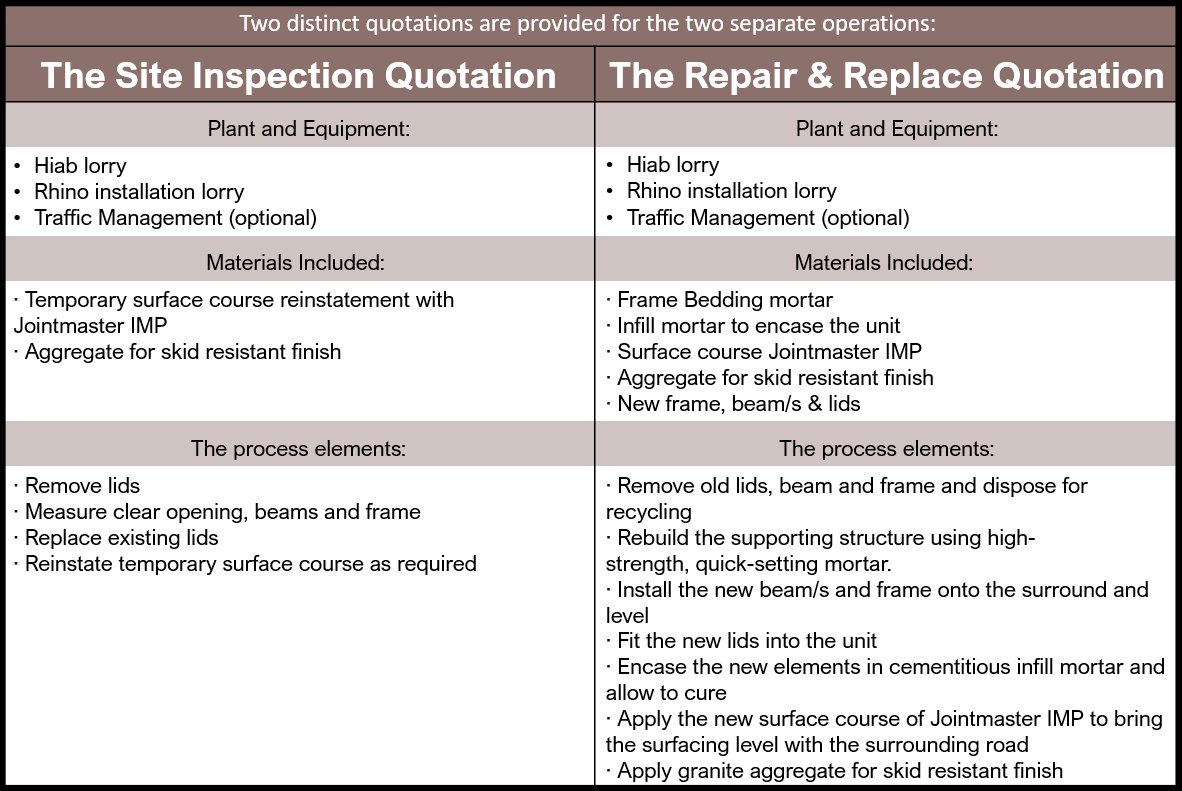

Step 1: Site Inspection & Assessment

An initial inspection is required to safely open the lids and measure the true clear opening—which often differs from the visible cover or internal chamber size. This visit includes:

- Hiab lorry and Rhino installation crew

- Lift plan and RAMS

- Temporary patching

- Traffic management

Temporary reinstatement is carried out using Jointmaster IMP (HAPAS Certificate 09/H149), ensuring safety and surface integrity until final works proceed.

Step 2: Bespoke Manufacture & Reinstatement

After confirming dimensions, we provide a full quotation and coordinate the manufacture of the custom ironwork unit. Replacement is then scheduled with minimal disruption. Our materials and methods include:

- Rapid-set, high-strength concrete bedding (25N/mm² in 1 hour)

- Fibre-modified backfill concrete (20N/mm² in 90 mins)

- Surface course using Ironmaster materials (HAPAS Certificate 06/H123)

The Ironmaster™ system, in use since 2006, is now the industry standard for resilient, long-life ironwork reinstatement—even in high-traffic areas and tunnels.

Our approach ensures your site stays safe and traffic-ready throughout—while delivering a permanent, engineered fix you can trust.

Modular Large Access Covers

Specialist Repair & Replacement for Complex Chamber Systems

Large modular access covers are often complex due to their size, weight, and site-specific constraints. These units are commonly found in tunnels, ports, car parks, and highways, and demand precise handling, fast-setting materials, and heavy-duty support systems.

At Rhino Asphalt Solutions, we specialise in the repair, re-bedding, and replacement of large modular ironwork systems. Our teams are experienced in working around critical infrastructure and can ensure both structural performance and long-term accessibility for maintenance teams.

Our Services Include:

- Re-bedding and adjusting modular frames and covers

- Full replacement of modular systems

- Inspection, measurement, and sourcing of replacement sections

- Lifting, cleaning, and re-greasing to preserve long-term access

Whether it’s a full-system replacement or a critical maintenance intervention, we provide end-to-end support with safety, speed, and compliance at the core of every project.

Tailored Installation of Modular Access Covers

We work directly with leading cover and frame manufacturers to ensure that every installation is fit for purpose—specifying the right materials and selecting optional features that suit your site’s demands.

Backed by our experience of installing over 10,000 Ironmaster units on UK highways, Rhino adapts its tried-and-tested Ironmaster™ system specifically for modular access applications. Our in-house crews are fully trained to deliver long-lasting, structurally sound installations—especially in complex environments like ports, tunnels, and multi-lane carriageways.

Using mobile lifting cranes, high-strength mortars, and our unique compaction-free surface finish, we ensure your modular system is installed safely, efficiently, and in full compliance with current standards.

Our Process

- Site Assessment

We begin with a full site visit to assess access, measure accurately, and confirm all technical requirements. - Off-Site Manufacture

Covers and frames are fabricated to exact specifications in collaboration with approved manufacturers. - On-Site Installation

Our specialist crews return to install the system using the adapted Ironmaster method—ensuring speed, safety, and durability.

Ready to Get Started?

Contact us today to arrange an initial site visit and discuss how we can support your modular access cover replacement or repair project.

Multi-spans

The Ironmaster system from Rhino delivers an engineering solution to replace, rebuild and re-bed multi-span access covers and frames.

Planned Maintenance for Modular Access Systems

In addition to full replacements, we support planned preventative maintenance on modular systems—an increasingly important part of asset management strategies. Regular inspection and re-greasing of hinges, checking for frame movement, and monitoring mortar deterioration can significantly extend the life of these units and reduce the risk of emergency failures. Rhino’s teams are equipped to carry out these works quickly and safely, ensuring continued access to underlying services while minimising disruption to traffic or operations.

✅ Typical Maintenance Activities Include:

- Visual inspection for frame movement, cracking, or bedding failure

- Lid lifting and hinge testing to confirm free movement and safe access

- Cleaning and re-greasing of hinges, locks, or lifting points

- Checking mortar integrity around frames and joints

- Identifying early signs of wear, deformation, or corrosion

- Tightening or replacing bolts where required

- Recording chamber condition for asset management systems

- Temporary patching where necessary until full repair or replacement

Fitting a Multi-span

Safety & Installation Protocols

At Rhino, safety is built into every stage of our ironwork replacement process. We follow strict operational procedures to protect workers, road users, and the public.

- Lift plans and full RAMS (Risk Assessments and Method Statements) are submitted for client approval prior to the commencement of works.

- A minimum working window of 8 hours is typically required for a standard installation, though timescales vary depending on the size and complexity of the unit.

- The final surface course is completed using our hot-applied Jointmaster IMP material—manually installed from the Rhino lorry into the recess around the new ironwork.

- A layer of granite aggregate is applied to provide a skid-resistant finish that meets highway safety standards.

- Once cooled and swept, the site is ready to be safely reopened to traffic.

This staged, controlled process ensures every installation is delivered efficiently—without compromising safety or surface performance.

Medway Tunnel Work

Multi-lid units are commonly found in tunnels and contain apparatus such as pumps. They can also have concrete filled lids. The measuring process is the same and installation work is unchanged. When planning the works, please take into account the timeframe for tunnel closure constraints, particularly the reopening times

Multi-lid units are commonly found in tunnels and contain apparatus such as pumps. They can also have concrete filled lids. The measuring process and installation work are the same. When planning the works, please take into account the timeframe for tunnel closure constraints, particularly the reopening times.

We rely on Rhino because of their system, certification, workmanship & reliability. They applied the same skills and attention to detail in getting the multi-span cover correct. It is a specialist job for which they are ideally suited

Rhino Asphalt Solutions Ltd were in all aspects of planning very professional, and the quality of their products at the Medway Tunnel are great.